The complete process undertaken from raw material to finished product is carried out in closed conveyor and pipes without touching by hand and thus avoided contamination from personnel.

The quality and success of operation of the product is based on the freshness of raw material, drying of the product, quickness without time delay in process, removal of water content from oil and seed, since these are the affecting factors of the shelf life and quality of the product, the whole process is devised to meet the above characteristics.

If the physical factors are satisfactory, the raw material is unloaded into the feeding pit. The material received in the factory is unloaded hygienically from the vehicle. If any of the lot is not met with the standard specification of company, that lot will be rejected. Sample are also taken for microbiological analysis such as TPC, E.Coli, V,cholera, staphylococci, and salmonella tested in our lab.

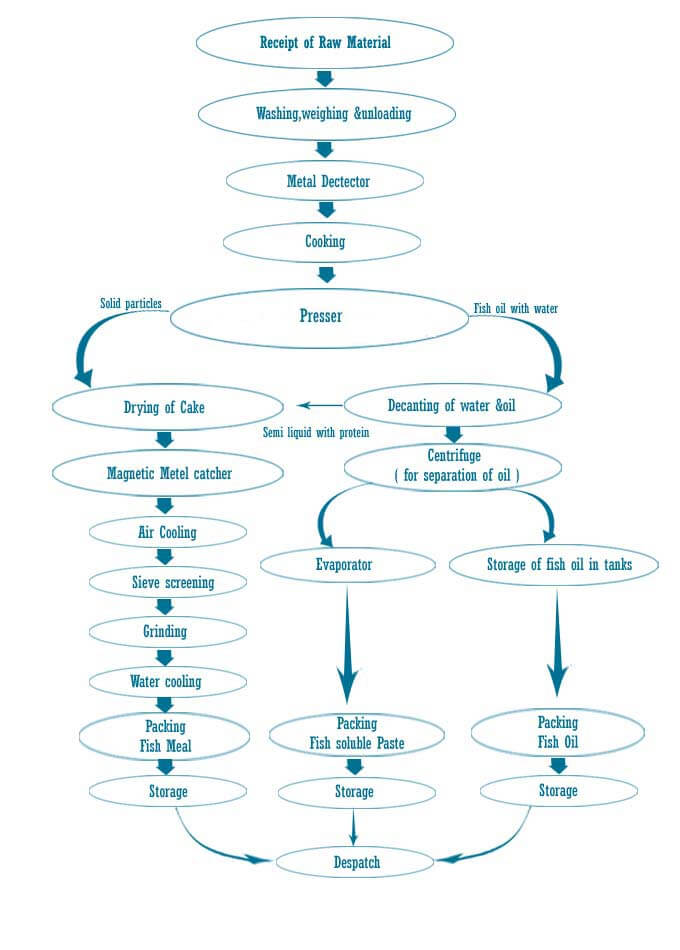

Fish meal are produced by a continuous process which involves cooking, pressing, drying and milling. We use raw material fully. The following summary is a step by step guide to the production process.

Washing weighing and unloading: This process is being used for the removal of slime and external matters such as dust and sand.

Cooking: Fish is cooked at 95 to 100 degree celsius for 15 minutes depending on the size in the cooking chamber.

Pressing: Screw presser is used for pressing the cooked fish. While Press Liquor (fish oil with water) and solids are separated and oil is collected in heating tanks.

Decanter: The Oil and water mixture is decanted and powder particles removed and decoded back to the cake.

Evaporator: The water segment accumulated from the separators is fed into the evaporators where it is concentrated before being blended with the presscake during the drying stage.

Drier: Drying is an important process to be carried out in producing quality fish meals. The work consists of removing the moisture using the Steam Dryer.

Sieve screening: The material is subjected to sieve screening where shell particles, born particles or any such foreign materials are filtered and removed.

Grinding: Then the material is powdered in the grinding machine.

Cooling: The material carrying conveyor is passed through a jacket where water is circulated through the outers pace of the jacket. Now it is ready for packing.

Packing: Fish meals are packed in HDPE poly bags in 50 Kg pack and it is stitched using machine.